Outlast is redefining insulation

After setting new global standards for textile heat and moisture regulation with its thermo-technology, the Heidenheim company Outlast is also providing a groundbreaking product group for insulation: AERSULATE®.

Aerogel – an impressive material

Aerogel is the world’s lightest solid and, with its extremely high air content, offers the best insulation value of all known solids in the world. Processing Aerogel is extremely complex, yet Outlast managed to bind the high-performance material to textile carrier materials using an innovative patented process. This marked the birth of AERSULATE®, a new type of insulation that exceeds conventional insulation materials in many respects. For instance, AERSULATE® requires significantly less space to achieve the same insulation values. AERSULATE® also works under the influence of pressure or moisture without any significant loss of function and, in combination with a fire-resistant carrier material, is flame-retardant. Processing is simple and involves conventional methods.

Outlast is redefining insulation

From ... Outlast developed the very thin material AERSULATE® using the most innovative processes, which surpasses common insulation in many respects and has impressive properties:

Space miracle

Characteristic for our AERSULATE® textiles is their low thickness at highest performance. While conventional insulation materials usually achieve their functionality through increased thickness, AERSULATE® products are true space miracles. Materials as thin as 1-2 mm can provide excellent insulation. This offers completely new potentials.

Top Performance

AERSULATE® products have an impressive thermal resistance. The German Institutes for Textile and Fiber Research Denkendorf (DITF) determined the following Alambeta key figures:

Result: When comparing identical non-woven substrates with and without AERSULATE®, Outlast Technologies achieves an increase in thermal resistance of more than 100%.

Material | Alambeta-Value |

Non-Woven without AERSULATE® | 20,4 |

Non-Woven with AERSULATE® | 45,0 |

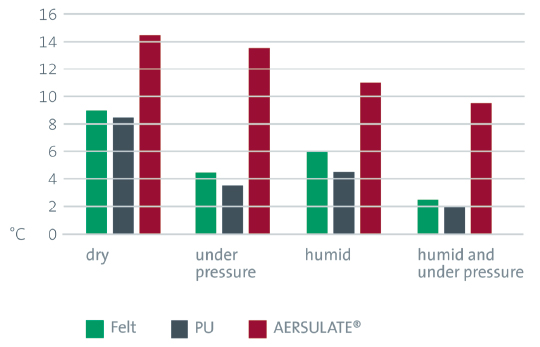

No problem with compression and humid conditions

Studies show that when AERSULATE® products are exposed to the thermal influence of a block of ice, they can keep away the cold significantly more than identical materials without AERSULATE® technology. Under pressure and/or humidity, this effect even increases.* Of course, similar effects will be seen when exposed to heat.

Additional properties

Our new high-performance materials also reliably resist boiling water. With a glove made of 1mm thick AERSULATE® you can easily reach into boiling water without scalding yourself. AERSULATE® not only insulates perfectly, it is also 100% water-repellent and very breathable. It also can be equipped with additional flame-retardant properties when requested.

Carrier Materials

We offer a wide variety of carrier materials, ranging from nonwovens and felts over multiple composite systems. The potential for AERSULATE® is immense.

Further processing

AERSULATE® materials are extremely robust and resistant but can be further processed very easily in existing manufacturing processes.

Sustainability

Aerogel is made from quartz, the base material of sand, and is therefore harmless to health and environment. Aerogel and the AERSULATE® product range are Made in Germany, guaranteeing the highest environmental and safety production standards.

* We will be happy to send you detailed information on further measurement results and the specific test setup if you are interested.

Wide Range of Using

The varied properties of AERSULATE® result in a wide range of possible areas of use. Here is a selection:

- Apparel of all kinds (e.g. work clothes, fire-fighting equipment)

- Footwear

- Helmets

- Tents

- Sleeping bags

- Technical applications

- Vehicles/aircraft

- Sun protection (e.g., windows, blinds)

- Cable/pipe sheathing

- Building insulation

- Intermediate layer in floorings

- Automotive

- Electronics

- Fire protection systems

- and much more

“When I saw Aerogel for the first time, I was really impressed by this exceptional material and its properties. Great that we have managed to make Aerogel accessible for many applications using a textile carrier material. I see a really wide field of application for our AERSULATE® materials that extends far beyond the classic textile market.”

Benefit together with us from AERSULATE® and its exceptional properties.

Contact us now! We look forward to discussing your personal application with you.